The Expert Guide to Merchandise Financial Planning

Merchandise financial planning, or MFP, is a critical retail business process in which companies aim to align enterprise-wide strategic financial plans to the execution of goals shared across functional areas. When done well, MFP establishes consumer-centric, omnichannel financial guidelines for retail inventory profitability and operational productivity.

In this expert guide, we provide a comprehensive overview of the retail merchandise financial planning business process and touch on related functional areas. We also address common mistakes and challenges The Parker Avery Group has witnessed through many client projects focused on MFP. Further, we explore MFP best practices and innovations that can help improve this key retail capability.

What is merchandise financial planning?

Merchandise financial planning (MFP) is a key retail process managed by planners or merchants and is essentially a seasonal checkbook guiding inventory investments. Since inventory is one of the biggest liabilities in a retail organization, managing this process is critical to ensure inventory investments are optimized and products are ultimately in the right place, at the right time. MFP is both a pre-season and in-season process, typically managed in a system such as Blue Yonder, Logility, o9 Solutions, Oracle, Relex, SAP, or ToolsGroup. In some cases, MFP is still performed in spreadsheets.

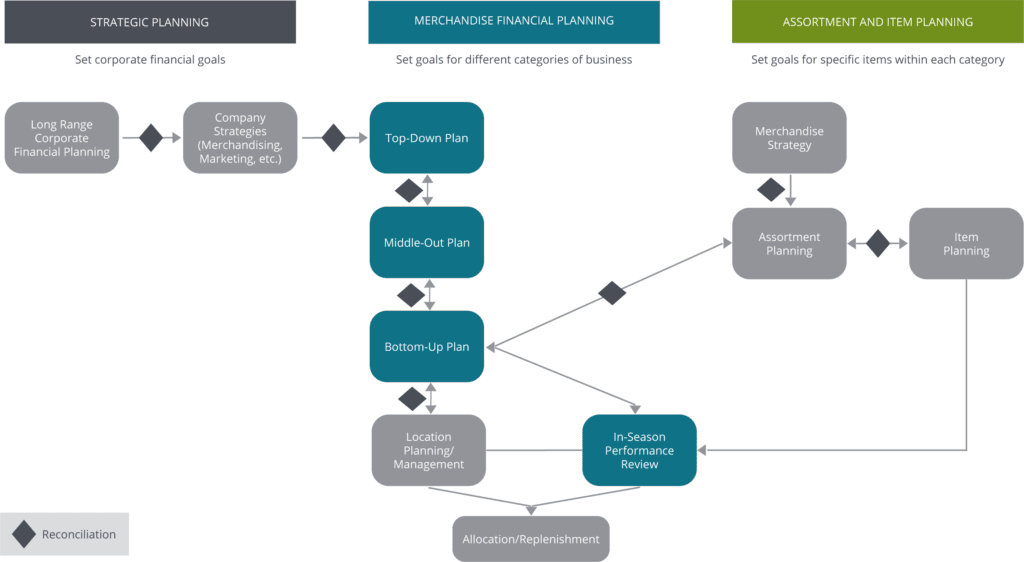

MFP fits between higher-level strategic planning and the more detailed assortment planning and item planning processes. Leading retailers ensure these planning processes are coordinated and reconciled at several points.

How MFP Fits into Retail Planning Processes

Top-down, middle-out, and bottom-up plans are all part of the planning process completed at different levels of the organization and in partnership with the buying/merchandising teams. MFP typically has two phases: pre-season and in-season planning; top-down, middle-out, and bottom-up plans are done pre-season.

Top-Down Plan

- Reflects the company’s financial plan and strategic targets

- Highest-level financial plan that incorporates large segments of the business

Middle-Out Plan

- Breaks the top-down targets into more actionable targets and smaller portions of the business (i.e., categories)

- This step is most prevalent when the planning team organization includes a middle management layer

Bottom-Up Plan

- Breaks the middle-out targets into smaller product groups (i.e., classes or subclasses)

- This step can happen in parallel to the development of the middle-out plan for a more objective comparison

- Bottom-up plans are compared to the middle-out targets and then one or both of those plans is adjusted as necessary

In-Season Performance Review

The objective of in-season performance reviews is to monitor planned versus actual inventory levels based on current sales and margin trends. These reviews establish guardrails that mitigate over- and under-buying as well as prevent loss of sales due to out-of-stocks.

Pre-season merchandise financial planning

Pre-season, budgets are created for sales, receipts, inventory, and margin at a common level of the product hierarchy (i.e., department/category or class based on the size of the organization). MFP will also include a location dimension (i.e., stores, e-commerce) and a time dimension (i.e., year, quarter, month). The MFP process is usually performed by a planning role, but, in smaller organizations, merchants and/or buyers may be tasked with MFP.

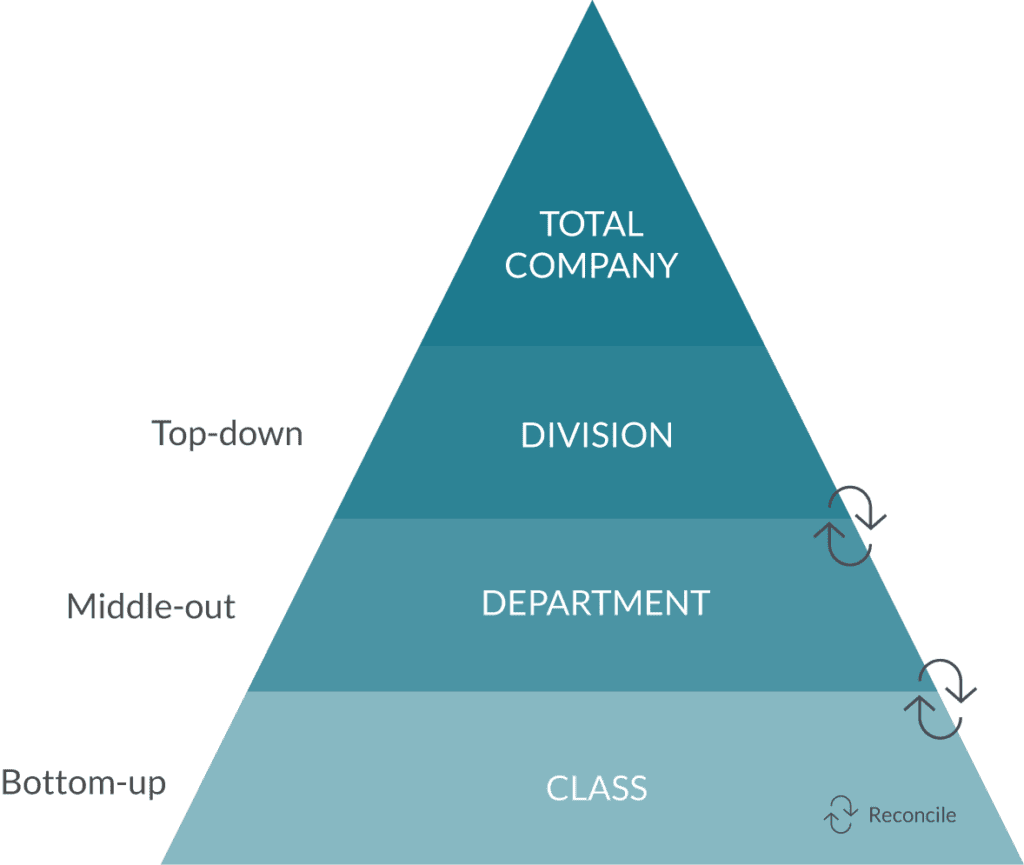

Merchandise financial planning can be multi-layered, typically considered top-down, middle-out, and bottom-up plans. These plans vary by level of the product hierarchy, complexity of the math, and the timing of the planning process.

Retail Product Hierarchy

Note: The image represents groups of products that make logical sense. Divisions may be mens, womens, kids, and home. Or, as in grocery, divisions may include produce, fresh meat, dairy, and frozen. Departments further divide divisions into logical groups. For example, the produce division may consist of fruits, vegetables, fresh juices, and salad dressing departments. Also, departments may be called “categories” in some organizations (e.g., grocery).

Pre-season (before a selling season begins), the merchandising organization will create a budget for the following year or season. This budget (or plan) can feed into assortment planning and item-level planning, allowing for reconciliation across different levels of the product hierarchy, as shown in the image. These plans may also be provided to the finance organization for their budgeting purposes. Plans can be created by channel (e.g., stores, e-commerce, catalog), as well as by wholesale and franchise partner channels. Some retailers choose to plan by vendor as well if there is close collaboration with the suppliers.

In-season merchandise financial planning

Once the pre-season plans are approved, in-season MFP management begins with actual performance data (i.e., product sales). In-season management focuses on adjusting planned sales and receipts to reflect current trends. During in-season, open-to-buy (OTB) meetings may take place to determine if money needs to be spent or moved across products.

What is OTB?

OTB stands for open-to-buy which is a financial budget for retail merchandise buyers. Simply put, this calculation helps retailers figure out how much inventory should be ordered to meet sales projections for a specific period.

A basic OTB formula is planned sales + planned markdowns + planned end-of-period inventory – beginning-of-period inventory.

OTB meetings occur once a month at most retailers.

| + Planned sales | $500 |

| + Planned markdowns | $100 |

| + Planned end-of-period inventory | $2,100 |

| – Actual beginning-of-period inventory | $2,000 |

| = Open-to-buy (OTB) | $700 |

What MFP capabilities are the most important?

- Facilitate plan visibility and reconciliation across organizational levels

Traditionally, many retailers perform MFP using the top-down, middle-out, and bottom-up approaches. We often find that retail leaders initially establish targets in a top-down or middle-out plan for three high-level areas: sales, margin, and inventory.

Planners reconcile with those targets when creating their more detailed bottom-up plans (often using a formal application or spreadsheet). Bottom-up plans typically include a full measure set, e.g., markdowns, receipts, inventory adjustments, and customer returns.

Having a single application for creating and reconciling these plans across the organization makes for a more efficient process. This allows leadership visibility to ensure bottom-up plans align with the original high-level targets before approving and locking plans down (i.e., finalizing).

Employ appropriate key performance indicators

Having the correct key performance indicators (KPIs) will help identify in-season trends (both good and bad), to make practical decisions about shifting money, requesting vendor returns (RTVs), canceling purchase orders, and managing/monitoring markdowns.

Common inventory-related KPIs include turnover, include turnover, weeks of supply (WOS which typically looks at history), forward weeks of supply (or forward cover, which looks at current inventory and determines how many weeks of future sales can be covered), and stock-to-sales ratio. Further analysis can take place by comparing the current year’s sales to last year’s or the approved budget as well as incorporating a demand forecast to help adjust sales going forward. Margin is closely looked at to evaluate markdown and promotional impact.

Accommodate financial and unit planning

While MFP typically focuses on financial planning, some retailers need to plan units as well. This approach helps provide an idea of the quantity of products that must be purchased for the upcoming year. If planning is done for a vendor, an agreement can be made regarding the number of items that will be purchased. This method typically involves vendor negotiations for financial compensation such as markdown money or promotional funds. If a company has a large private label business (they design and secure manufacturing for products under their own label), knowing units can help secure factory time in advance. Planning in units provides an estimate of how much is needed to be made, even if the exact product is still in development.

What common challenges exist with merchandise financial planning?

There are several common challenges in MFP from both a business and technology point of view.

MFP business challenges

- Overcomplicating the process

Making too many revisions pre-season leads to unnecessary churn in the organization, especially downstream in assortment planning which uses MFP values to stay on budget. Merchandise financial planning is not for perfectionists. MFP is done well in advance of actuals being generated and serves as a guide that should be revised regularly based on changing business needs.

Planning to short timeframes

During one client’s MFP implementation, the company wanted to do MFP at the weekly level. However, a purchase order could have a five-month delivery window. That meant that every week, they would have to roll planned receipts, which created unnecessary work and some guessing. Monthly MFP plans are detailed enough to support most retail businesses. Too much detail typically requires excess effort for little or no value.

Using too granular product level detail

In another merchandise financial planning project, the client wanted to plan at the subclass level (i.e., lower than class). However, there were 2,500 subclasses and four planners. Against our guidance, they believed the new system would make this level of detail manageable. Shortly after going live, the company realized managing MFP with granularity at the sub-class level was overwhelming. The Parker Avery Group was re-engaged several months after the MFP system implementation to adjust the lowest level of the product hierarchy to the class level.

Lacking defined checkpoints in the planning process

Employing a defined, multi-level reconciliation process (i.e., targets provided by leadership and plans created by merchants/planners) provides visibility into how lower-level plans roll up and compare to higher-level targets. It is important to follow a prescribed MFP process with distinct deadlines to avoid rushing and compromising the plan at the end of the planning period.

Inflexible MFP processes and tools

Even with the best plans and the most sophisticated retail demand analytics, the unexpected will happen. This could not be demonstrated better than during the COVID-19 pandemic and its continuing aftermath. A retailer’s MFP process and organization must be flexible to adjust as reality happens.

Flexibility can be reflected in several forms: system, process, and people.

- Flexibility within a system could entail a planning grid that pivots, has drill-down capabilities, and provides the ability to adjust plans at multiple levels with various reconciliation points. Additionally, the option to perform “what-if” scenarios would also provide flexibility.

- Process flexibility might present itself in the form of adding attribute planning with MFP to create a bridge between your plan and product selections during sensitive times such as a pandemic or weather disasters. This may include adding more meetings for process touchpoints to ensure the organization is reacting to the changing times.

- Finally, none of this would be possible without having an agile community of people who can quickly adapt to new circumstances as they arise.

MFP technology challenges

- Overcomplicating the initial design of an MFP system

When implementing a merchandise financial planning system, we are often told, “But I want to see it,” in sometimes hundreds of metrics/variables. In our experience, if a metric or variable is not planned or referenced, it should not be in the application. Reporting should be used to handle these types of requests. Furthermore, if the setup is too complicated, most merchants/planners will revert to their former legacy spreadsheets. Often, when spreadsheets are used, we see complicated linking of rogue files to get to a total value or manually duplicating data across spreadsheets and inputting results into the MFP system. This can lead to misinformation, incorrect calculations, and poor decisions. It can also lead to challenges with reporting and communicating results to other teams (e.g., finance).

- Trying to make a planning system something it is not

We see this issue when a client is trying to solve multiple challenges with a new planning system. A typical example is attempting to make the MFP system a reporting tool. These types of misunderstandings can be avoided with good process design along with carefully planned and well-executed communications and training vehicles that clearly outline what role each system has in the company’s planning process.

- The “magic button” defense

Often, we hear “I shouldn’t have to reflow receipts every week when actuals didn’t match the plan. Can’t the system do that for me?” Thought must be put into in-season planning activities because while most MFP systems are enablers of the business process, they are not the total solution. The roles involved in the process are the biggest asset, particularly those with in-depth knowledge of a category’s trends, supply chain issues, and weather impacts.

What characteristics are needed to excel with merchandise financial planning?

Retailers who excel at MFP understand the importance of actionable financial plans and employ a timeline for creating and reconciling their plans. Further, leadership and the roles accountable for planning are aligned on the strategy and the plan once it is finalized during pre-season planning.

Before going to market, every role in merchandising and planning should know the company’s strategy, how much money they have to spend, and expectations regarding sales, margin, and inventory goals. Keep in mind, based on the market offerings, companies still need to be nimble enough to move money from one product family to another.

There is a framework for teamwork between buying and planning to ensure alignment on goals. When one group is evaluated on sales and another on receipts/inventory, this approach can create stress as well as compromise planning effectiveness and financial results.

You may also like

What innovations can improve a retailer’s MFP capabilities?

- Use of demand analytics

Demand analytics represents a key innovation in merchandise financial planning. Retail planners are no longer required to run multiple reports to understand and communicate business performance. Analytics-driven MFP not only provides past performance via dashboards but more importantly gives guidance and even AI-driven predictions on future performance to manage the in-season planning.

- Flexibility to manage business disruptions

When COVID-19 shut the world down in 2020, either there was no performance history to use as a reference for brick-and-mortar stores, or e-commerce sales were inflated above normal performance because customers shopped more online. This was very apparent in grocery, as online shopping (delivery and store pick-up) increased. The pandemic was an extreme and unexpected experience for retailers, but there are many ways a business can be disrupted, even for a short time, including extreme weather, natural catastrophes, supply chain challenges, and sociopolitical issues.

As mentioned above, sophisticated demand analytics models can detect anomalies in demand far ahead of traditional timeframes. Integrating a modern demand signal into the MFP system can enable extreme flexibility and planning accuracy.

Further, the innovations showcased in merchandise financial planning systems at NRF’s 2024 Big Show represent significant strides in enhancing decision-making processes and adaptability within retail. Notably:

- The capability to generate forecasts instantly by selecting specific parameters and timeframes offers unparalleled agility, enabling retailers to respond promptly to market dynamics and consumer trends.

- The integration of weather data into sales and performance metrics provides invaluable insights, facilitating informed decision-making regarding inventory management and product placement strategies.

- The ability to dynamically adjust planning methodologies by selecting flexible and fixed measures in calculations underscores newfound flexibility in optimizing resource allocation and strategic planning initiatives.

These innovations not only streamline operations but also empower retailers with the tools necessary to navigate an ever-evolving market landscape with precision and foresight.

Beyond technology innovations that enable flexibility, retailers should evaluate purchase orders for delays in shipping or freight cost increases to identify potential new sources for products to fulfill OTB requirements.

Innovative retailers are increasingly considering factors beyond traditional sales history to identify current trends and make OTB adjustments, including crowd-sourcing and social media analysis.

Collaborative omnichannel planning and inventory management

When e-commerce was becoming mainstream, most retailers created separate merchandise financial plans by channel. In those early days of e-commerce, traditional retailers segregated inventory to ‘protect’ products so there was enough quantity available for customer sales through different channels according to the multiple plans. In a warehouse, this approach could mean that the exact same SKU may be slotted into two (or more) separate staging areas. If one channel was out of product, it could be a complicated process to transfer inventory between channels and could impact shrink.

Now, more companies are combining (or pooling) their inventory to employ the most efficient and cost-effective customer order management and fulfillment methods. With many different order fulfillment options (BOPIS, BOSS, BOPAC, ship to home, etc.), transparency in product location and quantities is key to better merchandise financial planning as well as optimizing order fulfillment and customer returns.

Final Word

The criticality of solid merchandise financial planning capabilities, particularly in today’s increasingly volatile consumer, macroeconomic, and global environment, cannot be understated. Leading retailers understand that planning processes can no longer be performed in functional silos. Collaboration across departments, along with advanced retail planning systems, is key to driving alignment of enterprise-wide strategic financial plans and ultimately more cohesive and successful execution of business operations.

If you have any questions about your own MFP business processes, supporting systems, or organizational structure, we encourage you to contact The Parker Avery Group.

Contributors

The Parker Avery Group is a leading retail and consumer goods consulting firm that transforms organizations and optimizes operational execution through development of competitive strategies, business process design, deep analytics expertise, change management leadership, and implementation of solutions that enable key capabilities.